The code indication changes as shown below, and notifies with a long beep.

Wall Mounted AC Inverter Unit

| Error Codes | Operation / Faulty Indication |

|---|---|

| E1 | Room air sensor contact loose / short. Check room sensor connection / change room sensor |

| E2 | Indoor coil sensor contact open. Check indoor coil sensor connection / change indoor coil sensor |

| E3 | Outdoor coil sensor contact open. Check outdoor coil sensor connection / change outdoor coil sensor |

| E4 | Compressor overload protection / Indoor / Outdoor coil sensor short. If running ampere highly increase, change the compressor. If not, replace the coil sensor |

| E5 | Gas leak. Check for leakage & repair / Top up refrigerant |

| E6 | Pump fault. Clear the clogging at drain pipe. If pump is not working, change the pump |

| E7 | Outdoor coil sensor exist (MS model). Remove outdoor coil sensor |

| E8 | Hardware error (tact switch pin short). Check for the tact switch pin condition |

| E9 | No Feedback from indoor fan. Check indoor fan motor / fan motor wiring |

| EE | EEPROM defrost |

Error Codes for G18 and GS02 – Inverter Y Models

Netware 3C / SLM 9 – Inverter Y Models (Except 5WMY-J/JR)

| Error Codes | Problem |

|---|---|

| 00 | Normal |

| U0 | Insufficient gas |

| U2 | DC voltage out of range |

| U4 | Communication error |

| U7 | Signal transmission error (on outdoor unit PCB) |

| UA | Installation error |

| UF | Communication Error (indoor and outdoor) piping and wiring |

| UH | Anti-freeze function in other room |

| A1 | Indoor PCB error |

| A3 | Water pump error |

| A5 | Antifreeze |

| A6 | Indoor fan motor abnormal |

| C4 | Indoor heat exchanger thermistor short/ open |

| C9 | Indoor room thermistor short/ open |

| E1 | Outdoor PCB error |

| E3 | High pressure protection |

| E4 | Low pressure protection |

| E5 | Compressor motor lock |

| E6 | Compressor start-up error |

| E7 | Outdoor DC fan motor lock |

| E8 | Ac input over current |

| E9 | EXV error |

| EA | 4-way valve error |

| F3 | Discharge pipe overheat |

| F6 | Heat exchanger overheat |

| H0 | Compressor sensor system abnormality |

| H3 | High pressure switch error |

| H6 | Position sensor abnormality |

| H8 | AC current sensor error |

| H9 | Outdoor air thermistor short / open |

| J1 | Pressure sensor error |

| J3 | Compressor discharge pipe thermistor short /open / misplaced |

| J5 | Suction pipe thermistor short/ open |

| J6 | Outdoor heat exchanger |

| J7 | Subcooling heat exchanger thermistor short/ open |

| J8 | Liquid pipe thermistor short/ open |

| J9 | Gas pipe thermistor abnormality |

| LC | Communication error (control PCB and inverter PCB) |

| L1 | Outdoor PCB error |

| L3 | Electrical box temperature rise |

| L4 | Heat sink overheat |

| L5 | IPM error / IGBT error |

| L9 | Stall prevention |

| P1 | Open phase or voltage unbalance |

| P4 | Heat sink thermistor short / open |

| PJ | Capacity setting error |

Sequential Controller (SQ LCD) – SB & RT Multi Compressors

| Error Codes | Faulty Indication |

|---|---|

| E01 | Require manual reset (possible causes) |

| E02 | Compressor 1 high temperature (overload) |

| E03 | Compressor 2 high temperature (overload) |

| E04 | Compressor 3 high temperature (overload) |

| E05 | Compressor 4 high temperature (overload) |

| E06 | Compressor 1 high pressure trip / contact open |

| E07 | Compressor 2 high pressure trip / contact open |

| E08 | Compressor 3 high pressure trip / contact open |

| E09 | Compressor 4 high pressure trip / contact open |

| E10 | Compressor 1 trip/low refrigerant/outdoor abnormal |

| E11 | Compressor 2 trip/low refrigerant/outdoor abnormal |

| E12 | Compressor 3 trip/low refrigerant/outdoor abnormal |

| E13 | Compressor 4 trip/low refrigerant/outdoor abnormal |

| E14 | Room sensor short |

| E15 | Room sensor open |

| E16 | Indoor coil sensor 1 short |

| E17 | Indoor coil sensor 2 short |

| E18 | Indoor coil sensor 3 short |

| E19 | Indoor coil sensor 4 short |

| E20 | Indoor coil sensor 1 open |

| E21 | Indoor coil sensor 2 open |

| E22 | Indoor coil sensor 3 open |

| E23 | Indoor coil sensor 4 open |

| E24 | Outdoor coil sensor 1 short |

| E25 | Outdoor coil sensor 2 short |

| E26 | Outdoor coil sensor 3 short |

| E27 | Outdoor coil sensor 4 short |

| E28 | Outdoor coil sensor 1 open |

| E29 | Outdoor coil sensor 2 open |

| E30 | Outdoor coil sensor 3 open |

| E31 | Outdoor coil sensor 4 open |

| E32 | Compressor 1 de-ice |

| E33 | Compressor 2 de-ice |

| E34 | Compressor 3 de-ice |

| E35 | Compressor 4 de-ice |

Error Diagnosis by Wired Controller (MC301)

| Error Codes | Meaning |

|---|---|

| F3 | Sensor Broken (indoor outlet coil) |

| F4 | Sensor Broken (indoor return air) |

| F5 | Sensor Broken (indoor supply air) |

| F6 | Indoor and controller communication malfunction |

| F7 | Ambient temp exceed the limit |

| F8 | 4WV malfunction |

| F9 | Refrigerant leakage |

| FA | Controller storage malfunction |

| FB | Water Pump (indoor water pump) |

| FC | Indoor and outdoor communication malfunction |

| FE | Master and slave communication malfunction |

| H0 | Digital comp overload |

| H1 | Fixed Comp1 overload |

| H2 | Fixed Comp2 overload |

| H3 | Fixed Comp3 overload |

| H4 | High pressure too high |

| H5 | Sensor broken, high pressure |

| H6 | Discharge temp too high |

| L0 | Super heat too low |

| L1 | Low pressure too low |

| L2 | Sensor broken, low pressure |

| 10 | System malfunction |

| 11 | Sensor broken (slave TH1 discharge temp) |

| 12 | Sensor broken (slave TH2 inlet coil 1#) |

| 13 | Sensor Broken (slave TH3 mid coil 1#) |

| 14 | Sensor broken (slave TH4 inlet coil 2#) |

| 15 | Sensor broken (slave TH5 mid coil 2#) |

| 16 | Sensor broken (slave TH6 inlet coil 3#) |

| 17 | Sensor broken (slave TH7 mid coil 3#) |

| 18 | Sensor broken (slave TH8 ambient temp) |

| 19 | Sensor broken (slave TH9 outlet coil) |

| 1A | Sensor broken (slave TH10 subcool outlet) |

| 1B | Sensor broken (slave TH11 subcool suction) |

| 1C | Sensor Broken (slave TH12 suction) |

| 1F | Emergency run (slave) |

| 20 | Outdoor storage (slave) |

| 27 | Ambient temp exceed the limit (slave) |

| 28 | 4WV malfunction (slave) |

| 29 | Refrigerant leakage (slave) |

| 30 | Digital comp overload (slave) |

| 31 | Fixed comp1 overload (slave) |

| 32 | Fixed comp2 overload (slave) |

| 33 | Fixed comp 3 overload (slave) |

| 34 | High pressure too high (slave) |

| 35 | Sensor broken, high pressure (slave) |

| 36 | Discharge temp too high (slave) |

| 40 | Super heat too low (slave) |

| 41 | Low pressure too low (slave) |

| 42 | Sensor broken, low pressure (slave) |

R410A Multi Digital Scroll System MDS-B Series

| Error Codes | Meaning |

|---|---|

| EC00 | 00## indoor unit communication |

| EC01 | 01# indoor unit communication failure |

| …. | 02~47# indoor unit communication failure |

| ER48 | Digital Compressor Overload |

| ER49 | Fix 1 Compressor Overload |

| ER50 | Fix 2 Compressor Overload |

| ER51 | Fix 3 Compressor Overload |

| ER52 | Discharge pressure too high |

| ER53 | Suction pressure is too low |

| ER54 | Outdoor unit’s IC error |

| ER55 | System Error |

| ER56 | Discharge temperature is too high |

| ER57 | - |

| ER58 | 4 way valve failure |

| ER59 | Ambient temperature is beyond the limit |

| ER60 | Emergency run |

| ER61 | Sub heating is beyond the limit |

| ER62 | Refrigerant released |

| ER63 | Slaver outdoor unit communication failure |

| ER64 | TH1 temperature sensor failure |

| ER65 | TH2 temperature sensor failure |

| ER66 | TH3 temperature sensor failure |

| ER67 | TH4 temperature sensor failure |

| ER68 | TH5 temperature sensor failure |

| ER69 | TH6 temperature sensor failure |

| ER70 | TH7 temperature sensor failure |

| ER71 | TH8 temperature sensor failure |

| ER72 | TH9 temperature sensor failure |

| ER73 | TH10 temperature sensor failure |

| ER74 | TH11 temperature sensor failure |

| ER75 | TH12 temperature sensor failure |

| ER76 | Discharge pressure sensor failure |

| ER77 | Suction pressure sensor failure |

| EC78 | All indoor units Communication Failure |

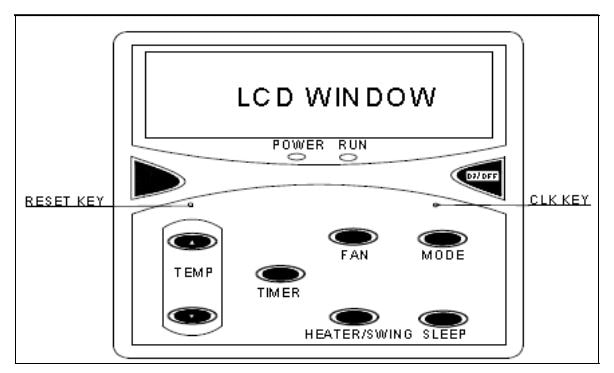

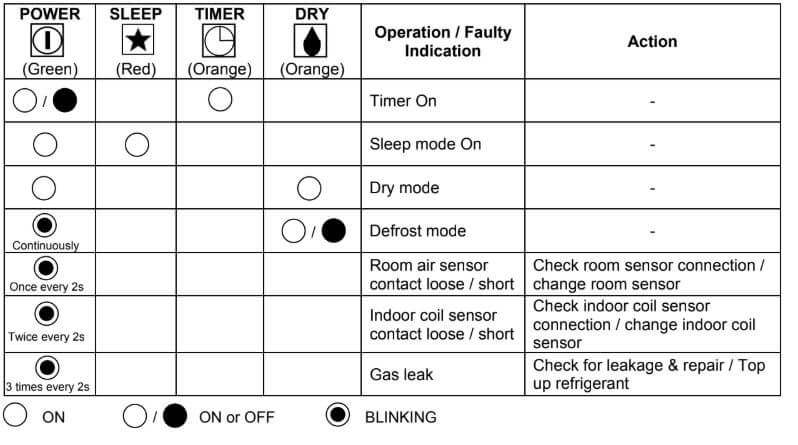

LED Lights Diagnosis Table

Troubleshooting

If any malfunction of the air conditioner unit is noted, immediately switch off the power supply to the unit. Check the following fault conditions and causes for some simple troubleshooting tips.

Fault: The compressor does not operate 3 minutes after the air conditioner unit is started.

Causes / Action: -Protection against frequent starting. Wait for 3 to 4 minutes for the compressor to start operating.

Fault: The air conditioner unit does not operate.

Causes / Action:

– Power failure, or the fuse needs to be replaced.

– The power plug is disconnected.

– It is possible that your delay timer has been set incorrectly.

– If the fault persist after all these verifications, please contact the air conditioner unit installer.

Fault: The air flow is too low

Causes / Action:

– The air filter is dirty.

– The doors or windows are open.

– The air suction and discharge are clogged.

– The regulated temperature is not high enough

Fault: Discharge air flow has bad odour.

Causes / Action:

– Odours may be caused by cigarettes, smoke particles, perfume etc. which might have adhered onto the coil.

Fault: Condensation on the front air grille of the indoor unit.

Causes / Action:

– This is caused by air humidity after an extended long period of operation.

– The set temperature is too low, increase the temperature setting and operate the unit at high fan speed.

Fault: Water flowing out from the air conditioner unit.

Causes / Action: – Switch off unit and call dealer

Fault: Hissing air flow sound from the air conditioner unit during operation.

Causes / Action: – Refrigerant fluid flowing into the evaporator coil

If the fault persists, please call your local dealer / serviceman

Acson Wall Mounted Split Systems AWM Manual PDF

Acson Ceiling Cassette Split Type Air Conditioner Manual PDF

Acson ART55A Rooftop Packaged Air Conditioners Technical Manual PDF

Comments